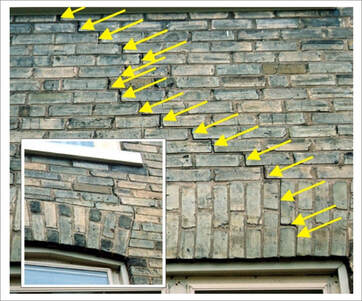

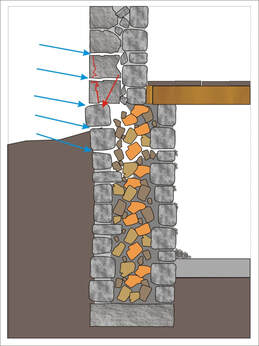

The Owner’s representative for a heritage brick masonry building wanted to repair the cracks highlighted within the photograph on the left - without a prior condition assessment. Retained as the consultant for the project, I observed that the cracks resembled those caused by differential movement within the natural stone masonry foundations. I also observed that previous attempts at repointing cracked mortared joints had failed. A review of the damp and deteriorated conditions within the basement confirmed to me that the below grade walls could not have been waterproofed. There was also evidence of debris that could only have originated from the inner core rubble of the traditional mass masonry foundation walls. I therefore concluded that the cause of the problem was the destabilization of the foundations due to water leaching the lime binder from the mortar/grout that had been used during their construction. (Illustrated by the Figure) I also concluded that it would be unwise to repair the cracked brick masonry - without first addressing the problem that caused the cracks. (I also did not charge for the ad hoc condition assessment!) WHAT WAS THE SOLUTION? Stainless steel helical masonry ties were installed from within the basement to provide the required restraint during grouting, to stabilize the walls during excavation work, and to provide a better composite action across the masonry assembly. The foundation walls were then exposed and waterproofed. The voids within the inner core rubble were then grouted using very low-pressure techniques to inject a lightweight cellular foamed cement grout. Finally the excavations were backfilled and cracked masonry joints were cut out and repointed using a hydraulic lime heritage repointing mortar.  This project is one of several case studies discussed within a chapter devoted to “Addressing the Cause - As Well as the Result” within MASONRY PROBLEMS Investigation, Identification & Restoration Canadian Project Case Studies

0 Comments

Leave a Reply. |

AuthorBased in Guelph, Ontario, Paul Jeffs founded PJ Materials Consultants in 1989 to provide specialist consulting services for North American construction-related industries. Prior to this, he lived and worked in several countries, including the U.K., Bahrain, Iran and Japan, and provided technical advice to many construction projects within the regions surrounding those countries. Paul specializes in providing materials-related technology advice for the construction, protection and restoration of concrete and masonry - and especially for the conservation of heritage buildings and structures. Archives

March 2023

Published Books

|

|

PJ Materials Consultants was formed by Paul Jeffs in 1989 to provide a wide range of specialist consulting services for concrete and masonry structures. The main business activity is divided between the provision of materials technology expertise and professional development technical training.

|