Case Study #4

Restoration of a Reinforced Concrete Structure

|

Problem:

Constructed in 1905, Cape Race Lighthouse is the oldest reinforced concrete lighthouse in North America and only the second of its type in the world. Unfortunately, the problem of concrete durability when exposed to a hostile environment was not well understood at that time and severe deterioration occurred during the first thirty years of its life. In 1937, in an attempt to correct the problems, a further 8-inch thick layer was added to the original 8-inch thickness. |

|

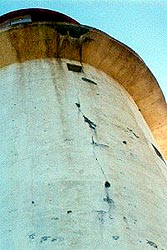

Unfortunately, the durability problems were still not sufficiently appreciated, further deterioration occurred and, once more - in 1969 - a 6-inch thick layer was added to the tower. However, welded wire mesh was included within the third layer - instead of structural reinforcing steel that was used in the previous two layers - and this contributed to excessive vertical oriented cracking from the effects of shrinkage and movement. In 1983, the cracks were repaired using a rigid mortar but - as it was not appreciated that the cracks were then serving as expansion joints to accommodate the differential thermal movement between all layers and areas of the tower - the repairs failed and further cracks occurred.

|

Solution:

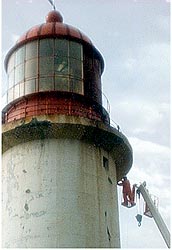

In 1996, PJ Materials Consultants was retained to carry out an investigation of the likely causes of the problem, provide a condition survey, and devise a restoration strategy to address the result of the problem. The investigation process included detailed archival research, a thorough evaluation of the condition of the tower - including compressive and tensile strength testing and the use of impact-echo technology to assess the most likely extent of hidden conditions - as well as a detailed structural engineering analysis. Based on the results of the investigation study, a restoration strategy was devised that utilized the outer layer as a protective barrier, after stabilization and repair of the structure. The restoration work included the removal of the existing coating from both the interior and exterior surfaces (the coating was reducing the ability of the concrete to dry) and the installation of flexible stainless steel ties across all three layers. The ties were installed from the exterior to terminate within the centre of the inside layer. They were resin-bonded within the inside layer, sleeved to prevent bond at the interface between the outer two layers, and then resin-bonded for the outer four-inches. Once the ties were installed, three expansion joints were formed through the full thickness of the outer layer and sealed with a joint sealant. A penetrating, highly "breathable" sealer was then applied to the outer surface - to reduce moisture ingress while facilitating moisture vapor egress. After a period of drying an elastomeric waterproof coating was applied to the exterior. Electronic monitoring devices were also installed to provide information regarding the rate and extent of drying in order that the application of an interior coating could be considered. However, although forced warm air drying was carried out for a period, it was eventually determined that a wiser course of action would be to leave the interior surfaces uncoated so they could dry over an extended period. The overall restoration strategy permits the outer layer to be permanently secured to the inner two layers, while improving the composite action of the layers. In addition, differential movement between the three layers can be better accommodated. This Case Study was featured in the May 200y issue of Construction Canada. Click here to view the article online. |